Brux Barrels, based in Lodi, Wisconsin, has earned a reputation for producing great-shooting tubes. Brux-made barrels have won their fair share of matches, and set some notable records in the process. A few years back, Rodney Wagner shot the smallest five-shot, 600-yard group (0.336″) in the history of rifle competition, using a Brux barrel chambered for the 6mm Dasher. Brux barrels are used by top shooters nationwide, and finish at the top consistently.

Owner Norman Brux has

been in the world of machines since he built his first rifle at 14.

He was trade-school trained as a tool, die and mold maker,

earning his apprenticeship at E. A. Schmid, and honed his

mold-making skills at F. J. Sipos.

Norm move to Wisconsin and

started KNB Tool Company in 1986, and founded Brux Barrels in 2006.

His parents were German immigrants and his father Klaus purchased

rifle-making machinery, aware that vintage equipment was the key to

quality machining. Norm rebuilt and re-engineered these machines to

provide the tolerances necessary for efficient, flexible barrel

fabrication.

His love for the work and the sport make Brux

the barrel of choice for many of the world's finest competition

shooters.

Owner Ken Clemens is a

native of Wisconsin, working on the family farm before beginning a

career with Marshall Erdman's Techline company that spanned 30

years. Ken worked at Techline for many years with Ken

Liebetrau, who left to begin making barrels at Brux. Ken followed

him to Brux, and after Liebetrau's retirement recently, partnered

with Norm as co-owner of Brux Barrels LLC.

Ken's

manufacturing experience, dedication to quality craftmanship and

customer service guarantee that the name Brux

represents the very best custom rifle barrels available.

What's the Secret?

Folks often ask why Brux barrels shoot so well. “What’s the secret?”. To make a cut-rifled barrel you have to start off with the proper ingredients: the best steel available, the best tools in the industry, skill, and experience. Since there are really only two main suppliers of barrel-quality steel, the skill and experience is what really makes a barrel maker stand out. Here is how Norman Brux explains all the procedures involved in making a Brux cut-rifled barrel:

Creating the Masterpiece - Step By Step

Step One

Material Selection

We start out with either 4150 chromemoly or 416R stainless

steel double stress-relieved stock. The stock starts

out at 1-9/32″ in diameter and 20-24 feet long We

cut to custom lengths per customer specifications.

Step Two

Barrel Contouring

The outside of the barrel is turned on a lathe and prepared

for drilling. As in each of the following steps, the barrel

is carefully cleaned after the process.

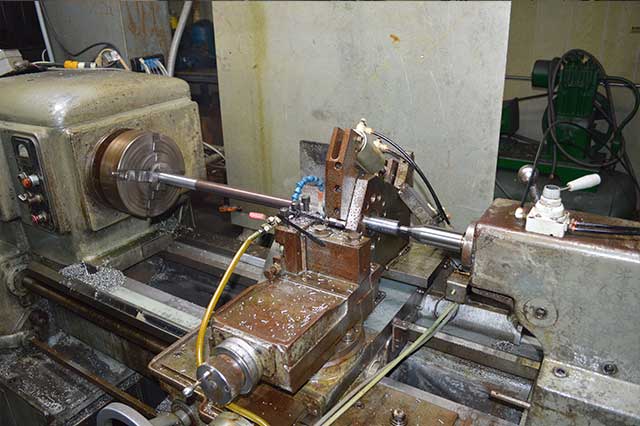

Step Three

Drilling

The cutter bit has holes through which oil or coolant is

injected under pressure to allow the evacuation of chips formed

during the cutting process. This is called “oil-through” or

“coolant-through”. The combination of a 3600 rpm turning speed

and good flushing allows us to drill a beautifully straight

and centered hole .005” under “land” diameter. Cleaning is done

again.

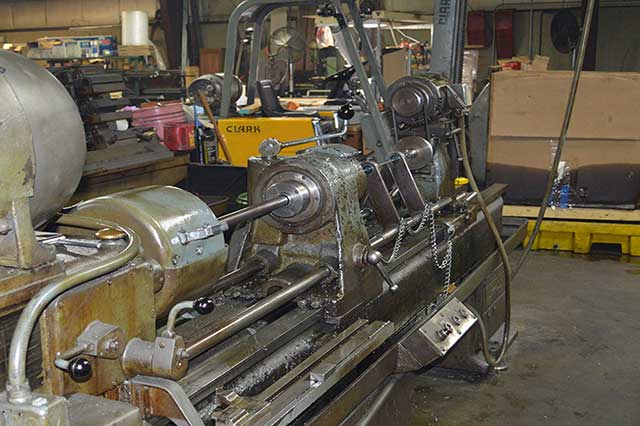

Step Four

Outside Contouring

The barrel is now sent back to the lathe for final contouring

of the exterior. Brux offers a variety of configurations and

the barrel is turned to exacting specifications and finished

to near perfection. A Monarch vintage lathe provides the high

quality of exterior turning, and our expert machinists ensure

that each customer's specs are met exactly. The barrel is cleaned

and prepared for reaming.

Step Five

Reaming

The blank is then sent to the Pratt and Whitney reamer

in which an “oil through” reaming tool is used to cut away

the extra .005” left in the drilling process. The reamer

makes an extremely accurate bore size ensuring a better

surface finish and the proper “land” diameter.

Step Six

Hand Lapping

We hand lap each barrel to remove any slight tool marks

that may have been left by the reamer and inspect every

barrel with a bore scope. If the barrel doesn’t meet our

standards for surface finish and tolerance it is discarded.

Lapping is a finishing process for the interior of the barrel.

We hand lap, as we believe in taking the time and care to

achieve the utmost mirror shine and smoothness of the barrel.

The barrel is cleaned again.

Step Seven

Rifling

The rifling machine is responsible for cutting

the all so familiar grooves in the bore. A caliber/land

configuration-specific rifling head is used to progressively

shave away small amounts of steel to form the rifling grooves.

This is accomplished by simultaneously pulling the rifling

head through the reamed blank as the blank is spun at a

controlled rate. This is the heart of the barrel-making

process, requiring decades of experience and dedication

to the craft.

Step Eight

Final Hand Lapping

Lastly, the barrel is hand-lapped again (to ensure a

smooth bore) as the final interior finishing process. This

time-consuming and precision procedure ensures the ultimately

smooth inner surfaces. A final inspection is performed with

the bore scope, then your custom BRUX Barrel is carefully

packed and prepared for shipping. Brux never takes shortcuts.

Every barrel is fabricated in this proven method, and many

critical elements are closely guarded trade secrets, unique

to BRUX.